Alcon Lighting, which works with America’s National Aeronautics and Space Administration (NASA) and commercial space companies, presents this Lighting for Space series to examine the unique requirements that come with lighting for space exploration. Topics addressed here and in upcoming articles focus on general issues without disclosing details to protect non-disclosure agreements (NDAs) with private and government space efforts.

Nothing travels faster than light. Consider the measure of a light year—the distance that light travels through interstellar space in the span of one year. According to NASA, that’s around 186,000 miles per second, totaling 5.88 trillion miles per year.

Lighting is essential to NASA’s endeavors—everything from launchpads to spacecraft and space stations, not to mention its many earthbound centers and facilities spread across the country.

Brandon Demeter, a former active-duty U.S. Marine and current lighting sales and specifications agent for Alcon Lighting, is well-versed in the challenges that come with lighting design for outer space. Demeter studied military intelligence, which led to a career in technology working on high-tech lighting projects for SpaceX, Lockheed Martin’s Orion capsule and Boeing’s Starliner spacecraft, among others. Demeter, who lives on Florida’s Space Coast near Cape Canaveral, shares his experiences with lighting aerospace and aeronautics facilities and how this affects his work in commercial lighting.

Were you a bit, pardon the pun, starstruck while working on these high-tech space projects?

I’m the third generation of my family to have done work at Kennedy Space Center, so there’s a normalcy to it. But then there is still the awe when you walk through a building and see on display a spacesuit that’s been to the moon. Lighting these projects is hard work and they are complicated, but it’s also easy because it’s something I’m passionate about. I mean, it’s space. I got to touch the aluminum core of a capsule being sent into space.

What makes lighting for space facilities so complex?

Like any other lighting project, you have to determine the right fixtures, placement and beam angles. But when you’re dealing with such a tight specification, you really learn the science of lighting. In many commercial lighting applications, you can go higher on your lumens and install a dimmer if you need to bring the levels down. But, for space applications, you’re running very specific photometrics and calculations. There are areas where you have to have fixtures that are rated for explosions and are pressure and vibration-proof because of the potentially volatile work they are doing.

Tell us about lighting a particularly challenging project related to space exploration.

A launchpad is a good example. Normally, you would think, I want to light this tower and I’ll need some really bright light, so I’ll just place fixtures here, here and there. With a launchpad, you have to consider the potential obstructions—how they are going to mount the fixture, where do they have the space to mount it and whether or not it’s in the pressure boundary—where pressure and vibration levels are too high. You end up learning about lights and their construction.

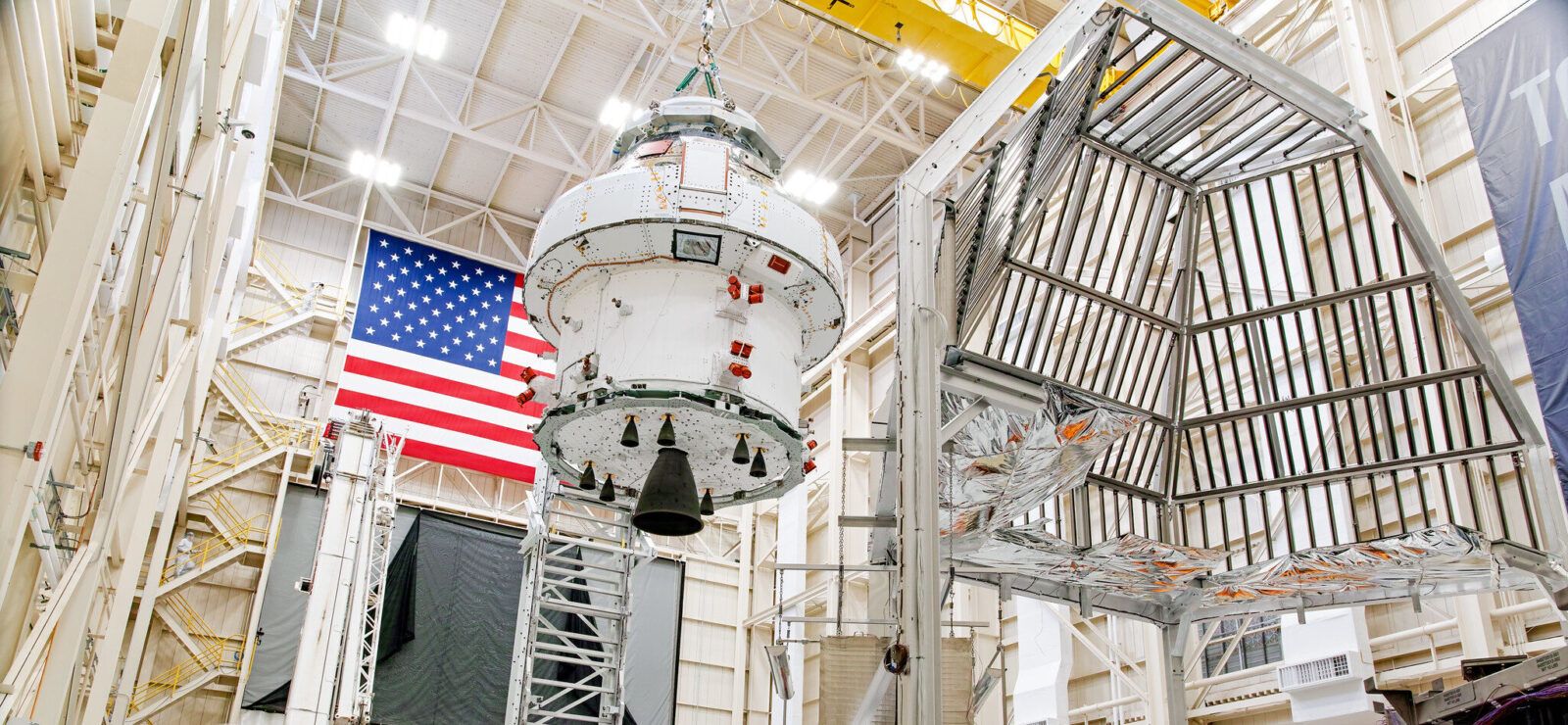

You’ve worked on lighting design for the facility where NASA’s Orion spacecraft is being built. What can you say about it?

I was involved in lighting design for the entire facility, which included a repurposed and renovated hangar which was previously used to service the Apollo. On a personal level, that was a really cool job [because it meant] going back to the moon and being able to have involvement in the development and manufacturing. I worked on the hangar where Lockheed Martin was putting everything together—the test cells, the integration, where they were actually building out the capsule. The project also included office lighting, which was pretty standard.

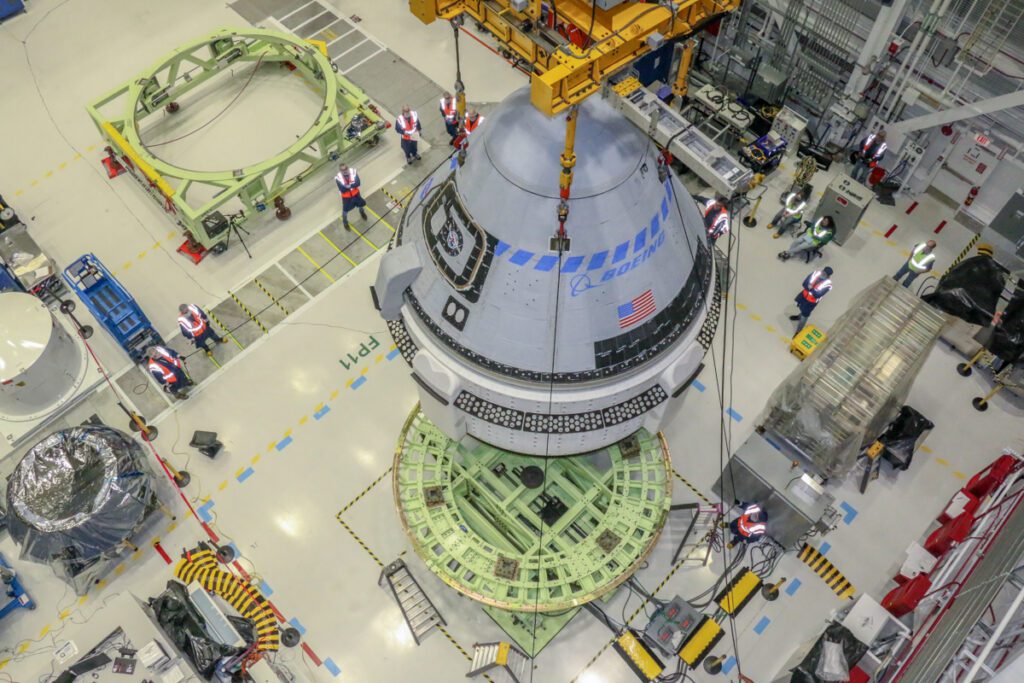

You also worked on the facility where the Starliner was built by Boeing. What were the client’s expectations? How did you meet them?

We only had around 85 spots on the ceiling that we could use, and the fixtures had to be around 100 feet up due to huge cranes that would be moving throughout the space. The client wanted to achieve 100 footcandles because it needed to be super bright, but they settled on 85 footcandles at the work level.

We managed to achieve the light level required, with our lighting calculations based on standard reflectance for a hangar floor. But, during a site visit, we realized the floor was a glossy white—it’s entirely ESD grounded which stops static discharge while working on electronics. Ultimately, the client, Boeing, wasn’t upset, because, due to this reflective floor surface, our design lighting levels were well above 100 footcandles.

What subjects did you study and what led you to work in the commercial lighting industry?

I studied military intelligence, which started me in technology. Around 10 years ago, I shifted to more standard commercial lighting applications, running AGi32 and photometric calculations, as well as network design and programs for lighting controls. I already had a basis in networking and programming, so it made for an easy transition to lighting.

How has your work with lighting for space informed your current work with Alcon Lighting?

In comparison to lighting these complex areas with tight specifications, lighting an office may seem simpler, however, they have more similarities than differences. It’s still a matter of choosing the beam spread, color temperature and what you want or need the space to feel like. People spend the majority of their daytime hours in commercial spaces and the studies and science of human-centric lighting help create the path for my work at Alcon Lighting.

The benefit of what I do now is carrying in a deep knowledge of lighting technology, lighting sizes, fixture calculations and construction and engineering of fixtures for every project. It can definitely help improve the customer experience.

Murrye Bernard is an architect and an architectural writer. She graduated cum laude from the University of Arkansas with a bachelor's degree in architecture. She was editor and director for Forward, the member's publication for the American Institute of Architects (AIA), as well as Contract Magazine. She writes about architectural design on Insights and serves as our architectural review expert.